Shenzhen Goldchip Electronics co.,ltd

业内外信息

Industry Information

一网打尽

An oven that can cook according to the amount and condition of ingredients, and an algorithmic trading system that can accurately determine the timing of stock trading based on market flrable to humans, and even devices that exceed human working capabilities have appeared in some application methods.

Asmart robot that can flexibly perform tasks using sensors and AI

In the past, home appliances and information systems could only strictly complete various tasks according to the sequence and conditions determined in advance. Its advantage is that even when the use environment changes, it will not perform operations other than the preset ones, but at the same time, it also has the problem of being unable to adapt to changes flexibly. Of course, even this type of conventional equipment has the advantage of being able to work quickly and correctly automatically, and it can be said to have played a sufficient role in many respects.

On the other hand, recent smart devices and systems can flexibly respond autonomously, and their scope of application has expanded to work fields that have relied on human hands until now. The effect of such smart devices and systems is particularly significant in the manufacturing industry. It can sense individual differences in workpieces and fluctuations in work quality during production, and adjust production conditions autonomously, so as to maintain work efficiency at a high level. Smart factory of quality.

In terms of industrial robots, this intelligent trend is particularly significant. So far, industrial robots have been mainly used to automate monotonous repetitive tasks and tasks that are dangerous and laborious for humans. However, due to the lack of operational flexibility like many previous devices, its use is also very limited. Today, industrial robots are able to perform tasks that were previously performed by humans because of the need for flexibility.

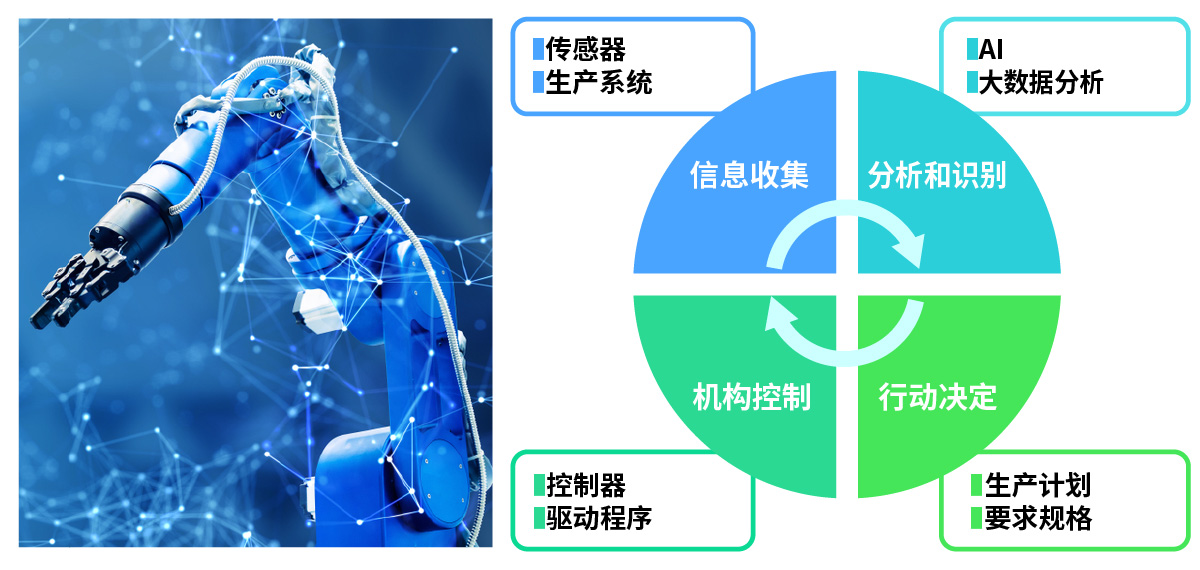

In recent years, intelligent robots have made remarkable progress, and their interior can continuously perform four tasks of "information collection", "analysis and recognition", "action decision" and "mechanism control" (Figure 1).

Among them, in the process of information collection, the data of the surrounding environment and even the information of the production system are generally collected through cameras and sensors. In the process of analysis and identification, based on the collected data, high-end information processing technology such as artificial intelligence (AI) is used to judge the situation. In other words, it can be said that a smart robot is a high-end IoT system. In the next step, the action decision process, it is necessary to decide under what conditions the robot should operate in order to achieve the goal. After this stage, if the required actions can be correctly determined based on the collected information, there is not much difference from the FA technology used to control industrial robots in the past. In addition, it is necessary to control the motors that drive the movable parts of the robot such as the robot arm and the manipulator through mechanism control.

In semiconductor factories, autonomous control of robots by linkage with production management systems

What kind of work do intelligent robots undertake in advanced factories today, and what effects do they bring? The following is an example of a semiconductor factory and an automobile factory, that is, two advanced factories that require completely different work contents.

The first is the semiconductor factory. In semiconductor factories, silicon wafers are processed and processed to produce chip products with intricate circuit diagrams drawn on them. The characteristic of semiconductor factories is that the automation and labor saving of processes and operations on the production line have been pushed to the limit. The purpose of doing this is because if people enter the factory, the people themselves will become the main reason for reducing the chip yield.

In recent years, in the semiconductor industry, with the development of the horizontal division of labor in design and manufacturing, product manufacturing is often entrusted to companies that can produce various types of chips. Such companies are called foundries. In the foundry, the type of chip manufacturing can be adjusted according to the market demand and the production plan of the design professional manufacturer, which is the so-called variant variable production. At the same time, since the order and conditions of the processing and handling of each type of manufactured chip may be different, frequent step changes or changes in the transfer destination between devices often occur in the factory. A mechanism that reduces manual intervention and can respond flexibly only through machines and systems.

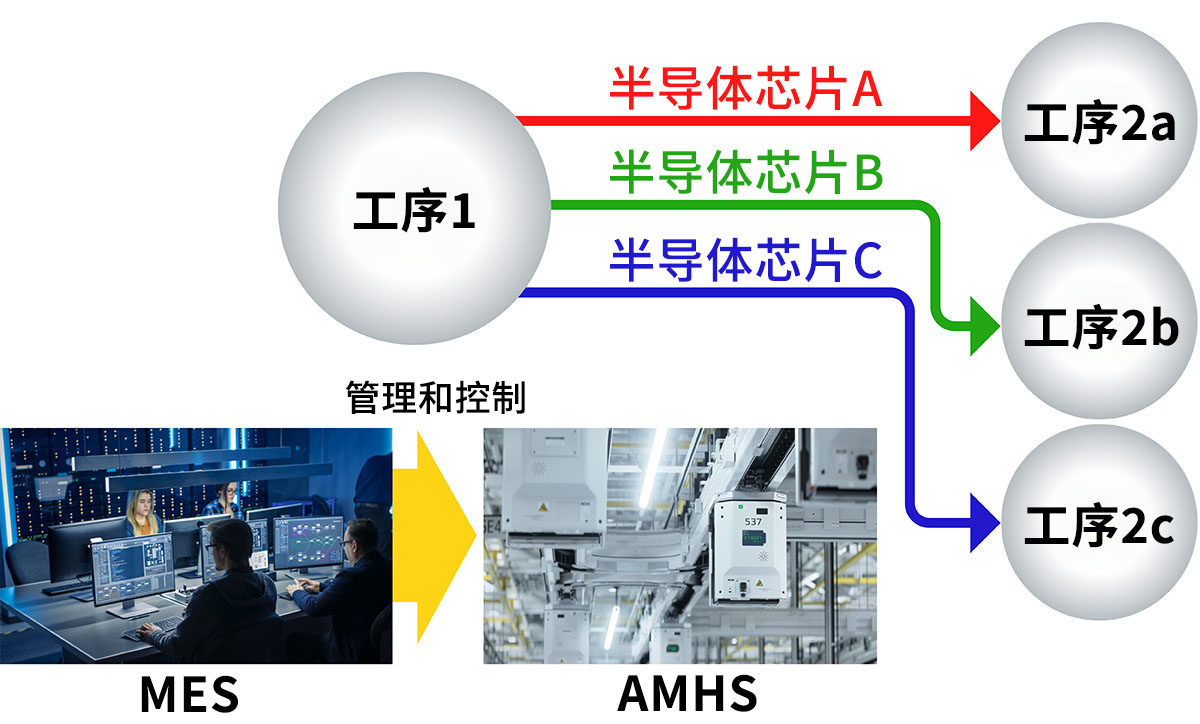

It is intelligent robots that meet such requirements. A transfer robot called AMHS*1 (Fig. 2) is used in the transfer between different processes in semiconductor factories. In order to maximize the production efficiency of semiconductor factories, a mechanism that can carry out timely transportation according to the production schedule and the progress of each process is indispensable. Therefore, the operation of the AMHS used for transportation between different processes is linked to the MES*2 that manages the processing of each process and its conditions, transportation, etc., and autonomous control enables it to carry out transportation at the ideal timing.

*1 AMHS is the abbreviation of Automated Material Handling Systems, translated as automatic material handling system, which is a kind of AGV (unmanned distribution vehicle). In general, the system lifts boxes containing FOUPs (single batches of wafers) along rails set on the factory ceiling and transports them to their destinations.

*2 MES is the abbreviation of Manufacturing Execution System, which is translated as Manufacturing Execution System. It is an information system that can realize the visualization of the status and actions of devices, processing, and processing objects on the production line, and provide assistance to operators and support decision-making. In semiconductor factories, in many cases, the information system automatically adjusts and controls the operating conditions of robots and devices without human judgment.

In a car factory, humans and robots coordinate assembly and inspection processes

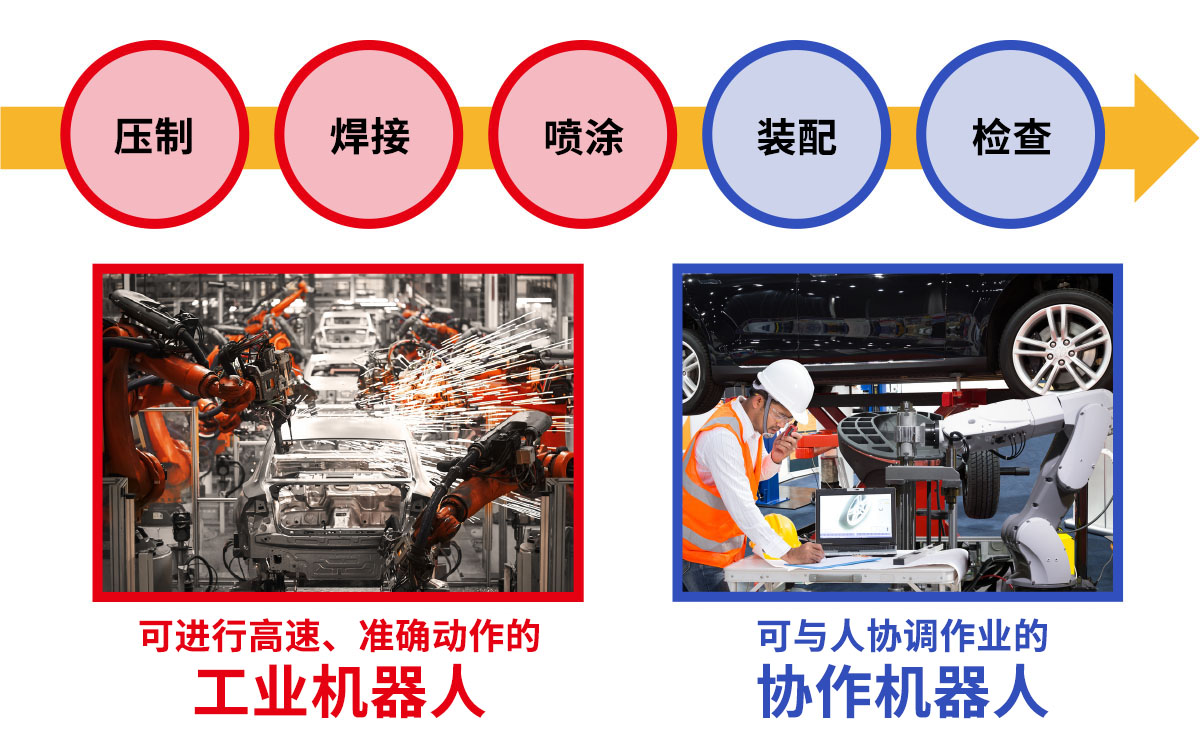

Next, let's look at the situation of the car factory. It is said that each car currently has about 30,000 components. In the vehicle factory, through the five processes of "pressing", "welding", "spraying", "assembling" and "inspecting", various parts and materials are assembled in a complex and accurate manner to complete the production of vehicles. And each process uses a variety of different robots.

Among the 5 processes, the 3 processes of pressing, welding and spraying have achieved the same labor saving as the semiconductor factory. The reason for this is that the materials used in the work are often heavy or have the potential to expose people to harmful gases and chemicals. Therefore, large-scale and agile multi-axis robots and the like are often used in these processes. For this type of robot, the requirements for its speed and accuracy are higher, often exceeding the requirements for intelligence.

On the other hand, in the assembly and inspection process, although robot technology has been highly evolved, there are still some operations that must be done manually, because some of the work requires precise adjustment of the position of the parts, accurate force is required during installation, or must rely on human hands. Human sensibility is checked, etc. However, since not all operations need to rely on human hands, in order to improve operation efficiency and quality, it is also necessary to further improve the automation level of robots. In addition, robots that can coexist with humans and coordinate operations are often used here, and we call them collaborative robots*3 (Figure 3).

*3 Collaborative robots refer to robots equipped with safety-enabling features. It is possible to coexist with people on the same work site without preparing a safety barrier, and to perform linked operations with people.

Advances in collaborative robots have been remarkable in recent years. At present, some robots have the function of paying attention to the operation progress of nearby workers and coordinating smoothly. When using manual operation, each person's work proficiency, physical condition and fatigue may become factors that affect work efficiency. Therefore, in order to improve the working efficiency in the process, it is necessary to coordinate the actions of the robots working together so that they can keep pace with the work of humans.

We predict that robots active in factories will become more and more intelligent in the future. Its development is mainly due to several aspects, including sensor technology for data collection, industrial network technology that can share information between devices and equipment, and even advances in advanced information processing technologies such as AI. The importance of electronic components and semiconductors for intelligent robots will surely increase in the future.